European Logistics Partner: Movement, Assembly, and Positioning of Battery Cabinets in Data Centers

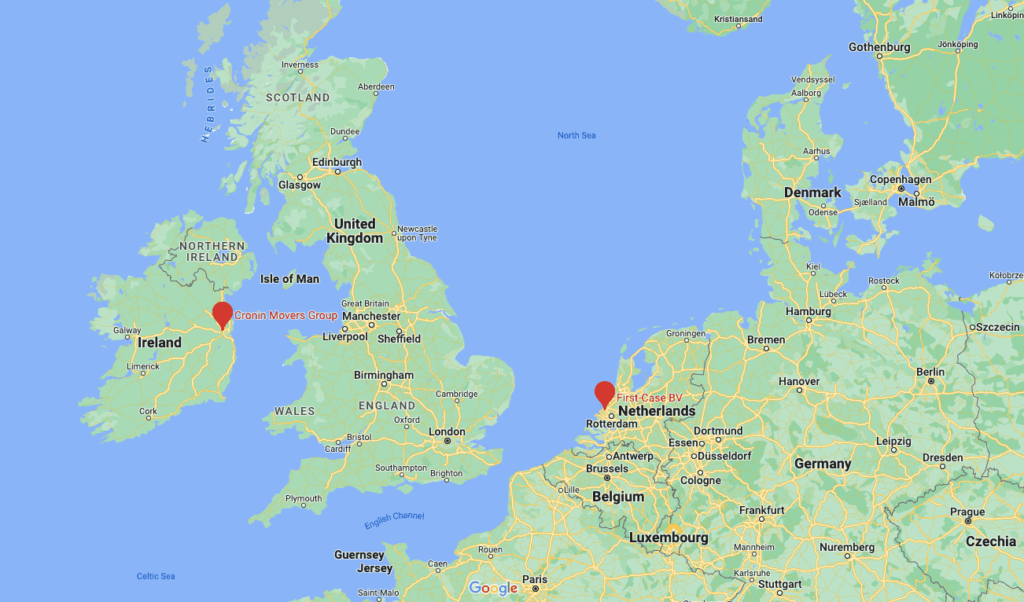

First-Case, headquartered in The Netherlands, is renowned across Europe for its exceptional Technical Logistics services. Specializing in the intricate realm of Technical Logistics, they efficiently handle the transportation, assembly, and strategic placement of high-value server racks and battery cabinets for Data Centres throughout Europe. In a strategic move, First-Case and Cronin Specialist Logistics have forged a collaborative partnership, extending their high-quality services to Ireland. This agreement aims to uphold the same rigorous standards synonymous with the Data Centre industry that clients have come to expect from First-Case.

WHAT WAS INVOLVED

In executing the battery cabinet movement, assembly, and positioning project for Data Centers, our mission was to provide comprehensive support to First-Case. Operating with a proficient on-site team in Ireland, we orchestrated the logistics associated with unloading and transporting battery cabinets into a Colocation data center (Colo). Within the Colo, our team oversaw the final assembly, precise positioning, and the crucial battery connections. These installations play a pivotal role in sustaining uninterrupted and efficient data center operations, particularly during power outages.

The Specialist Logistics team at Cronin had prior experience working in data center environments and adhering to stringent on-site protocols. Our crew boasts accreditation in safe pass, manual handling, and working at heights training.

Undergoing rigorous, customized training with First-Case instructors, our team covered site induction, 5-point PPE, daily toolbox talks, Risk Assessment Method Statements (RAMS), Standard Operating Procedures (SOPS), and security protocols.

Collaborating closely with First-Case’s client in Ireland, our team meticulously facilitated the movement of battery cabinets from the landing pad to the Colo. This involved adhering to strict on-site movement protocols, ensuring safety, and maintaining security within the facility throughout all movements.

Our team expertly positioned the anchor battery cabinet on designated floor markings, securing the remaining units to the anchor. The top box units were then installed atop the cabinets, with cabling meticulously run to the battery cabinets. Clad in specialized arc flash clothing, our team loaded the batteries into the cabinets and connected them using specialist insulated tools. To meet specifications, all battery cabinets were leveled using shims, and the distance from the wall was measured to ensure compliance.

THE RESULT

The Data Centre battery cabinet movement, assembly, and positioning involve numerous crucial outcomes. Essential elements include adherence to on-site protocols, strict observance of health and safety guidelines, meeting client deadlines, ensuring site security, and completing all tasks on-site to a high standard.

David Dowling, the Commercial Director, expressed the significance of this highly specialized work, stating, “This is highly specialised work and is really valued by our partner and their client, there is an unbelievable synergy between First-Case and Cronin Specialist Logistics. Their commitment to quality really fits with our ethos of exceeding expectations and working to the highest professional standards.”

The client’s feedback has been outstanding, and as a testament to the Specialist Logistics team’s performance, the client extended the project from an initial 3 Colos to now covering 10 Colos, keeping the Cronin team notably busy!

OUR SITES

Spacious Office Relocation integrating Hybrid Work Practices

A major multinational technology company aimed to streamline its operations by consolidating two office locations into a new campus in Dublin City. Concurrently, the company sought to implement organizational changes to support hybrid working and hot-desking practices. This extensive office relocation, integrating hybrid working methods, demanded meticulous planning and efficient execution to minimize business disruption.

WHAT THE PROJECT INVOLVED

The new campus was partially operational, hosting 800 staff. To initiate the move, an additional building on the campus was brought into operation, relocating 400 staff members. This preliminary move took place on day one, allowing the subsequent four days for the primary relocation.

The main relocation encompassed moving 1,000 workstations and equipment to the new campus, with 400 workstations designated for hybrid working or hot-desking. This strategic shift enabled the company to provide a mix of assigned, reservable, and drop-in desk facilities for staff.

Apart from relocating staff and equipment, including pedestals and operator chairs, we provided desktop IT disconnection and reconnection services to facilitate the move.

Ensuring accuracy in the multitude of moves was a key challenge. To address this, pre-printed color-coordinated move labels were supplied for the project, ensuring the precise transfer of crates, furniture, equipment, and pedestals within defined zones on the relocation plan.

As part of the relocation, approximately 1,000 pedestals were removed and disposed of from the new location. These pedestals, associated with workstations designated as hot-desks without personal storage, were temporarily relocated to a holding area during the process to avoid obstruction on work floors before the first day of business. Careful scheduling allowed our team to complete the moves and remove the pedestals when all key workstation moves were finished.

THE OUTCOME

The entire relocation was successfully executed within a tight 5-day timeframe, providing our client with a seamless transition for staff. By coordinating staff to work from home on specific days, normal business operations remained uninterrupted throughout the process.

Offloading and Positioning of NPW Tanks

Conducted on behalf of our client, Jones Engineering, this NPW Tank Offloading and Positioning project was an integral part of a broader initiative to establish a new processing line for a Food/Beverage processing plant.

Jones Engineering, a prominent mechanical, electrical, and fire protection contractor, operates globally, serving Ireland, the United Kingdom, Central Europe, Northern Europe, and the Middle East. With a century-long track record, Jones Engineering has experienced sustainable growth in both size and reputation, boasting a turnover exceeding €750 million and a workforce exceeding 4,000 people worldwide.

PROJECT SCOPE

The NPW Tank Offloading and Positioning project demanded meticulous planning and the expertise of our Machinery Movers Team. Reporting directly to the onsite Project Manager, our team executed a professional rigging and moving service.

PHASE 1

The initial phase centered on offloading the Non Potable Water (NPW) tank from the transport trailer. Employing a JMG MC250 electric pick & carry crane, the tank was carefully lifted off the transport trailer and securely placed on purpose-built stillage stands using soft slings.

PHASE 2

The subsequent phase involved the ‘top & tail’ maneuver and the precise positioning of the NPW Tank within the processing plant. Considering engineering drawings for other plant equipment, the all-electric JMG MC250 crane adeptly lifted the tank, maintained in a horizontal position, and maneuvered it into the plant room. The slings were reconfigured to the top and bottom lifting eyes of the tank.

Utilizing the JMG MC250 at the top and a forklift at the bottom, the tank was cautiously maneuvered into the upright position. Once in the upright position, the forklift was disengaged, and the JMG MC250 carefully transported the tank to the designated location, setting it down in its final position.

THE OUTCOME

The team leader expressed utmost satisfaction with the project’s outcome, marking it as a success from initiation to completion. The large NPW tank was effectively offloaded and placed in the precise location, without impeding other critical tasks within the area. The project concluded within a day, allowing our client to proceed seamlessly with the remainder of the processing plant setup.

Relocation of Fragile Artifacts

PROJECT DETAILS

The basement hosted a substantial and delicate compilation of zoological artifacts, encompassing items of diverse sizes. Notably, this collection featured 250-year-old skeletons suspended in their current position from existing internal structures.

Ensuring the secure relocation of these skeletons necessitated the creation of custom transport poles. These poles were threaded through existing ropes to bear the weight of the skeletons. Subsequently, new slings were introduced and fastened to suspend the skeletons from the transport poles.

Manually extracting the collection of skeletons from the basement, suspended on the supporting poles, posed a unique challenge. The delicate process involved transporting them across campus, where they were then carefully transferred onto purpose-built A-Frames in their new designated location.

Given the age and fragility of the artifacts, particularly the skeletons and bones dating back 200 to 250 years, the relocation team exercised extreme caution. Negotiating the basement environment presented specific challenges, with tight turns, narrow passageways, pillars, and overhead ducts. Consequently, the team shielded the artifacts with bubble wrap and other protective materials during transit. To navigate through the basement’s complexities safely, a spotting system was employed to identify potential contact points, ensuring a secure passage.

PROJECT OUTCOME

The intricate task resulted in the successful transfer of the delicate zoological artifacts to their new locations, including the sizable and unwieldy skeletons of a camel and an ostrich. These skeletons now hang securely from their new A-Frames, eagerly awaiting examination by prospective Zoology students in the future.